Machine

- Home

- »

- Machine

Our Machine

Steel Fencing Posts Machines for Producing Peach-Shaped, Round, Square, Rectangular Posts, T-Posts, Y-Posts, and Star Pickets

Anderil Steel Fence Posts Co., Ltd. offers specialized Steel Fencing Posts Machines designed for efficient and precise production of steel fence posts. These machines are essential for industries involved in fencing applications, where the need for high-quality, durable posts is paramount. The equipment is capable of producing a variety of fence post cross-sections, such as Y-shaped, T-shaped, and Peach-shaped profiles, based on customer specifications.

Introduction to Equipment

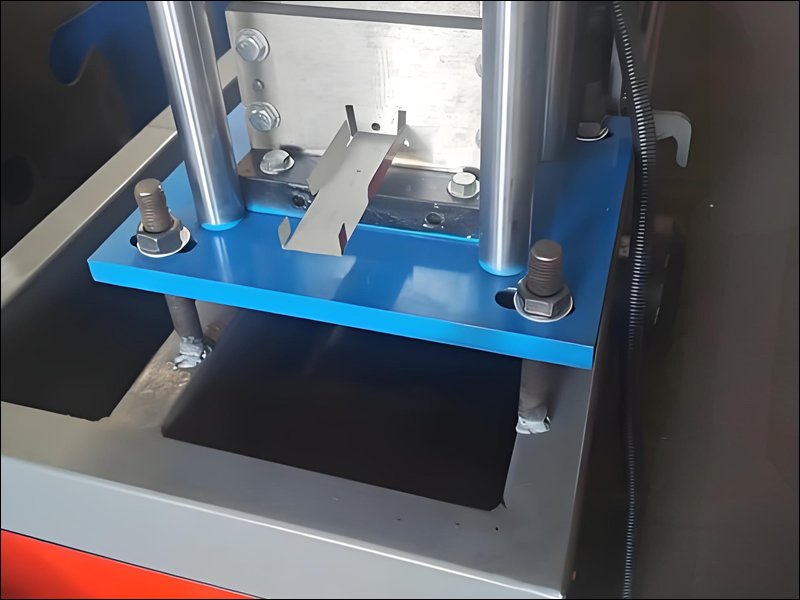

The Steel Fencing Posts Machines is a specialized cold bending forming equipment that processes steel coils (strip steel) through a series of continuous operations such as uncoiling, leveling, punching, cold bending, and cutting. This process results in the production of Steel Fence Posts, including Y-shaped, T-shaped, Peach-shaped, and other cross-sections. The entire production line typically consists of the following machines:

- Hydraulic Uncoiler (3-5 t steel coil capacity)

- Five-Roller Leveling Machine

- Servo Feeder

- Hydraulic Punching/Notching Machine (programmable hole positions and notches)

- Main Roller Cold Bending Forming Machine

- Hydraulic Flying Saw or Cold Shear for cutting

- PLC + Touch Screen Fully Automatic Electric Control System

- Material Collection Table (with optional stacking or packing machine)

Main Features and Performance

- High automation: PLC control throughout the process, with formula changeover in less than 5 minutes.

- High precision: Hole spacing ±0.5 mm, length ±0.5 mm (for lengths up to 6000 mm).

- Smooth forming surface without scratches and burr-free cut ends.

- Rollers made from Cr12/GCr15, hardened to HRC58-62, with a service life of over 800,000 cycles.

- The entire system occupies about 25-30 m × 2 m × 2 m, weighing 10-20 tons. The production line only requires a 380 V/50 Hz/3-phase power supply and an air source of 0.5 m³/min at 0.7 MPa.

- Optional remote I/O interface for easy integration with MES systems.

Technical Specifications (Typical Configuration Example)

Raw material thickness: 0.8-2.5 mm (commonly 1.0-1.5 mm)

- Raw material width: ≤400 mm

- Line speed: 0-15 m/min (infinitely adjustable)

- Main motor power: 7.5-11 kW

- Hydraulic system power: 3-5.5 kW

- Punching/Notching pressure: 16-25 t

- Cutting method: Flying saw stoppage, Cr12MoV blade

- Length tolerance: ≤±0.5 mm

- Roller material: Cr12/GCr15, hardened to HRC58-62

- Control system: PLC (Panasonic/Mitsubishi) + 7-10″ Touch Screen

- Equipment dimensions: Approx. 12 m × 0.9 m × 1.1 m

- Total weight: Approx. 11 t (10-20 t depending on configuration)

- Warranty period: 1 year (2 years for key components)

Applications

The processed posts can be paired with double twist wire, frames, peach-shaped posts, round posts, and other mesh types for use in high-speed railways, highways, airports, factory areas, residential communities, and warehouse isolation. The post cross-section can be customized according to customer drawings. Common specifications include 48×1.5 mm, 50×2.0 mm, and 60×2.0 mm, with heights ranging from 1.8 to 2.4 m, available with flange base or embedded type.